How to choose the right trash can liner for your room

How to choose the right trash can liner for your room

HDPE (High-Density Polyethylene) and LDPE (Low-Density Polyethylene) are two different types of polyethylene, which are widely used in various applications due to their unique properties. The main differences between HDPE and LDPE are as follows:

Density: The primary distinction between HDPE and LDPE lies in their density. HDPE has a higher density, which means it is more rigid and has a higher strength-to-weight ratio. LDPE, on the other hand, has a lower density, making it more flexible and less rigid than HDPE.

Strength and Rigidity: HDPE is stronger and more rigid than LDPE. It is commonly used in applications where a high level of strength and structural integrity is required. HDPE is often used for products such as pipes, containers, and heavy-duty bags.

Flexibility: LDPE is more flexible than HDPE, making it suitable for applications where a certain degree of flexibility is essential. It is commonly used for products like plastic films, wraps, and squeeze bottles.

Chemical Resistance: Both HDPE and LDPE have excellent chemical resistance, but HDPE is generally more resistant to chemicals, making it suitable for applications where exposure to harsh chemicals is a concern.

Transparency: LDPE is more transparent than HDPE, making it suitable for products that require a clear or translucent appearance, such as plastic bags or wraps.

Processing Methods: HDPE and LDPE are processed differently due to their varying properties. HDPE is processed using methods like injection molding and blow molding, while LDPE is typically processed through extrusion techniques.

Environmental Impact: Both HDPE and LDPE are considered to have a lower environmental impact compared to other plastics, and they are both recyclable. However, HDPE is generally more widely recycled due to its higher density and demand in the recycling market.

In summary, HDPE is stronger, more rigid, and has higher chemical resistance compared to LDPE. LDPE, on the other hand, is more flexible and transparent. The choice between HDPE and LDPE depends on the specific application and the desired properties needed for the end product.

Types of Trash Bag Seals

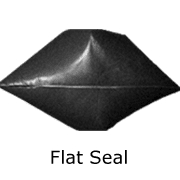

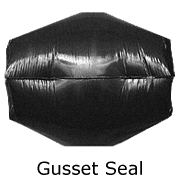

Seal is a term used to describe the bottom of a trash can liner. Seals come in three types: star, flat, and gusset.

- Star Seal: The most common seal in the industry, star seals are manufactured by folding the bottom of the trash can liner over several times and then sealing it. This virtually eliminates leaks, allowing the liner to conform to the shape of the trash can and distribute the refuse evenly around the bag.

- Flat Seal: Manufactured by simply sealing the bottom edge so that no length of the can liner is sacrificed, flat seals provide a generally leak-proof product. They do not, however, conform well to the waste receptacle and can be difficult to handle.

- Gusset Seal: Manufactured with both sides of the bottom edge tucked in to form gussets, gusset seals are reinforced at the indented outer edges with four layers of film while the middle of the bag is sealed with two layers. This causes a tendency to leak with wet trash.

Introducing Trust+: the ultimate solution for all your waste needs. With its sturdy design, drawstring closure, and odor-blocking technology, Trust+ ensures a hassle-free and hygienic trash disposal experience. Upgrade today and experience the convenience and reliability you can trust.